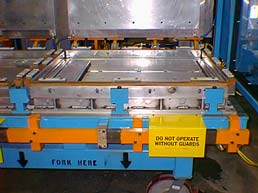

- This foam fixture was designed with casters for portability and intended for use as a self contained foam system with PLC logic to control machine functions such as lid open/close/lock functions and door push-offs as well as temperature control and cure time.

- The two views above show the door crowding tooling, locking mechanism, and push-off in one of our portable foam fixture designs.

- MLS Systems has performed retrofit work on many existing cabinet foam lines. We have also built many new cabinet foam systems.

- One of our skilled technicians inspecting a foam fixture during a retrofit project on a case foaming system.

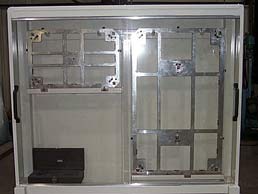

- This foam fixture was designed for prototype work and low volume production. This fixture was designed to be portable and flexible with adjustable lid lock heights and foam pour angles.

- This gage is designed to check tooling location on a cabinet liner foam fixture.

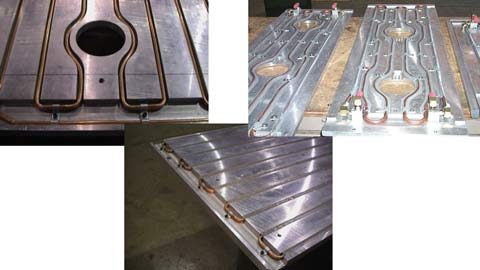

- MLS Systems has gage making capability. These gages were designed to check door foam fixture cavities to insure dimensional consistency of doors from fixture to fixture on an MLS Systems built foam system.

- Prototype foam fixtures built to test case foam properties before the final production tooling is built.