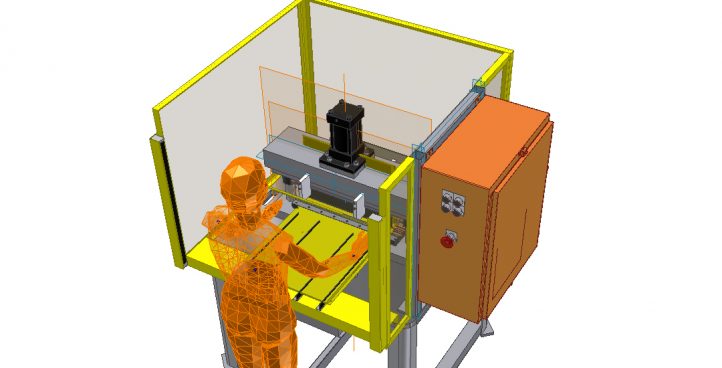

Thanks for visiting MLS Systems, the home of single source responsibility in the design and manufacturing of quality automatic and semi-automatic material handling, welding, and assembly systems. MLS Systems has been providing high quality automation solutions for all manufacturing sectors including appliance and automotive industries since 1979. Our machines can be found in factories worldwide including many “blue-chip” manufacturing companies.

MLS Systems is a systems integrator providing custom designed and built equipment for medium to high volume production facilities. As a custom capital equipment supplier, we provide single source responsibility for equipment ranging from small single station machines to multi-station production lines. We offer innovative new turnkey or retrofit solutions for all your special equipment needs. MLS Systems has an experienced staff of engineers in house to provide mechanical engineering and electrical controls engineering design solutions to meet your needs and budget. Our skilled manufacturing department offers in house coordinate measuring capabilities for verifying that your equipment and products are manufactured to the tight tolerances that today’s industry demands. Our experienced and friendly staff will work closely with you from the initial design and build phase of your project through installation on your factory floor. We specialize in on time deliveries as well as unparalleled installation support